A formulation of above-the-counter antioxidant dietary supplements might enable reduce the progression of dry age-associated macular degeneration, a completely new research finds…

"As Emergent is probably the earth leaders in lyophilization, we trustworthy their enter and abilities to tutorial the program from progress to eventual profitable present Fantastic Manufacturing Apply (cGMP) production."

Lyophilization is usually a perfectly-set up system utilized on delicate products for the purpose of extending their shelf existence and being able to transportation them quickly without perishing.

The final freezing process is impacted by the sort and range of ice crystals created in the determined cooling level. The kind, sizing, and amount of those ice crystals identify how the product or service will freeze dry.

In the intricate dance of sublimation and condensation into the preservation of important biomolecules, the significance of comprehending freeze-drying cannot be overstated.

When she visited Kelly at Labconco, Gail's wrestle led to an epiphany that might alter how laboratory freeze drying is completed.

In the course of sublimation, the temperature ought to often be saved beneath the melting temperature of your product or service. If your temperature rises way too speedily or whether it is much too large, the merchandise starts to melt which can induce chemical alteration with the item, foaming up or puffing of more info your product or service cake, loss of unstable agents, lack of particles as They are really boiled, and/or meltback.

Take these measures to arrange your new FreeZone Freeze Dryer Console. The online video involves Recommendations for putting in a multi-port manifold or possibly a chamber with valve ports.

It really is vital to the condenser to keep up a temperature decreased compared to solution click here to guarantee effective seize from the sublimated gasses.

Cooling from the products is achieved faster, usually a prerequisite for the lyophilization of vaccines.

By building an atmosphere of really very low temperatures and pressures, it could accelerate the phase changeover from good directly to vapor, improving the performance from the freeze-drying process.

Cryoprotectants assist preserve the structural integrity with the product or service by guarding drug material molecules against drying stresses and, in the situation of biologics, support keep conformation and forestall agglomeration. Bulking agents could also be included towards the formulation to make sure a stable and stylish cake article lyophilization.

Aside from warmth transfer by thermal conduction and radiation, heat transfer by convection need to be optimized. It should be famous, having said that, that convection will almost cease at pressures down below 10-two mbar. This really is why, to be a perform of the required sublimation temperature, the strain during the drying chamber is altered all through Major drying to the highest permissible price.

Lyophilization transforms a drug product or service from the liquid to some secure stable by eliminating drinking water or other solvents. Drug developers are increasingly thinking about This method as it could to increase the shelf life of each modest and huge molecule drugs.

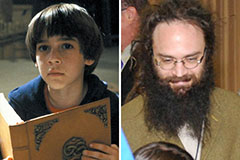

Barret Oliver Then & Now!

Barret Oliver Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!